The life of a rubber track is dependent on several important factors, which all go towards contributing to the length of time it will last. Some of these factors include:

- The surface conditions the track is operating in. As you can imagine, if your excavator or Skid Steer is operating in harsh, rocky and abrasive surfaces, this will quickly attribute to significant wear and tear on the rubber track, reducing its capacity to perform as it should and survive the full length of its lifecycle, usually estimated at 1 to 2 years for rubber tracks under normal operating conditions.

- The amount of regular maintenance undertaken on the undercarriage. Maintenance or lack of will directly affect the performance of the equipment and as a result the life expectancy of the rubber track fitted. The more regular the maintenance the longer the rubber track will last.

- The type of equipment the rubber track is fitted to. Whether it’s a small mini-excavator or a large Crawler Carrier, the life of the rubber track will be affected by the type of machine its fitted to e.g. a skid steer only operates in constant motion while an excavator or drilling machine is operating even when stationary, reducing the wear and tear on the rubber tracks.

- The operator of the equipment. An operator’s driving/operating style will have a direct impact on not only the equipment but the rubber track with a cautious and steady operator less likely to cause long lasting damage to the track as opposed to an operator who is aggressive in his driving approach.

- The type of rubber and how the rubber track is assembled. A major factor in determining how long a rubber track will last is the quality of rubber compound and the manufacturing process used. A track manufactured poorly or utilising poor quality rubber compound will as a result last a lot less than one made utilising a high-quality rubber compound and manufacturing techniques such as continuously wound high tensile steel cables and steel core bars, which add significant strength, flexibility and durability to a rubber track.

The manufacturing process and rubber quality is why a DEKK Rubber Track is far more superior than most competitor rubber tracks being supplied in Australia.

A Dekk Rubber Track has undergone strict manufacturing, design and testing processes before being approved for sale and consequently we’re confident in the quality and ability of our Rubber Tracks and Pads to meet the demands of the Australian earthmoving and construction industry and can offer an industry first and only 24-month Full Replacement Warranty on all our Excavator Rubber Tracks and a standard 12-month Replacement Warranty on all other DEKK Rubber Tracks.

With supporting evidence from customers and our own testing to back it up we’re quietly confident that a DEKK Rubber Track has lasted up to 4 years under general operating conditions, well in advance of the 1 to 2 years.

A DEKK Rubber Track has 4 core attributes which go into making it a superior Rubber Track and extending its life expectancy from an industry expectation of anywhere from 1 to 2 years depending on the key factors mentioned earlier to up to 4 years in some cases with a DEKK Rubber Track. These 4 core attributes are:

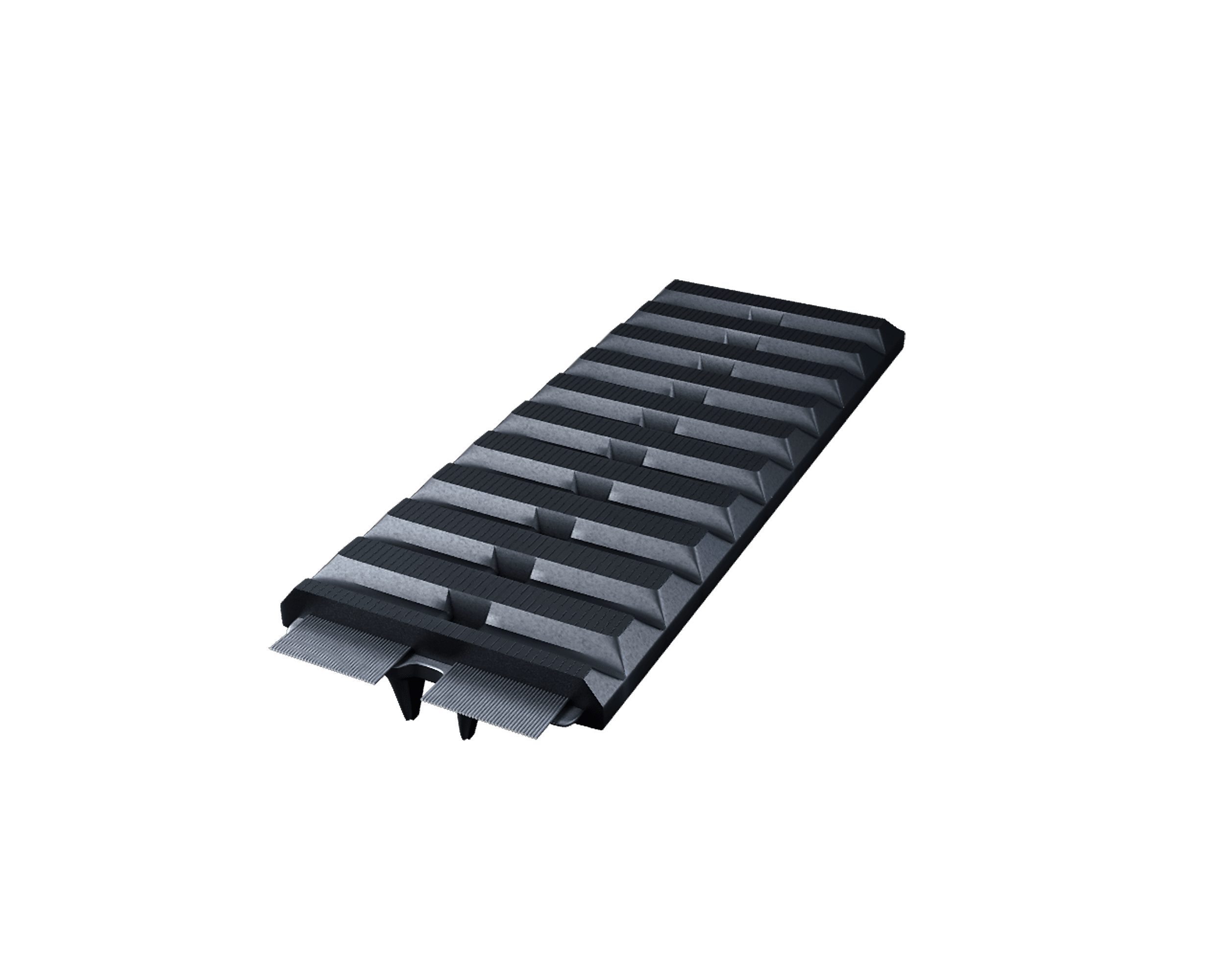

- Utilise a continuously wound, high tensile steel cable design to help prevent corrosion, provide greater strength and flexibility and eliminate cable joins, which are a weak point in the design and found in most other competitor tracks.

- Steel core bars are fitted for maximum strength and reduced risk of de-tracking.

- Tread patterns designed for improved traction to minimise surface damage and wear and tear on the track.

- Manufactured using heavy duty rubber compound for greater flexibility and wear resistance minimising the risk of punctures and overall ensuring that the Rubber Track can handle any surface with maximum performance.

So, the next time you’re choosing your next Rubber Track, take these factors into consideration to ensure you choose the right track for your equipment.

Contact our Customer Support Team to help you choose your next Rubber Track by calling 1300 335 528, email [email protected] or SMS your enquiry to 0437 030 370.